플랜트산업펌프

DWG Series

Vertical Multistage Pump Booster Pump System

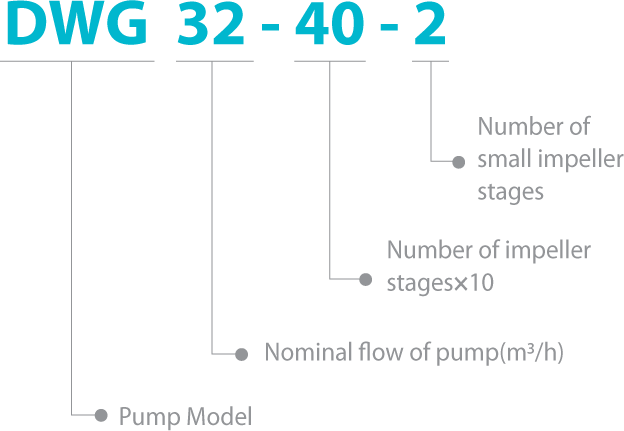

표준형식

MOTOR SPEC(Standard)

Standard 3 phase squirrel cage motor

- Motor type : TEFC

- Protection grade : IP54

- Insulation grade : F grade

- Flange type : Round type flange

- Standard power spec : 7.5kW 3 - phase 220/380V

APPLIED FIELD

- Fluid like with low viscosity and without fiber or other foreign matters that cause damage, ex) drinking water, cooling and heating water and condensate water (except acid or alkaline liquid)

※Allowable fluid temperature: -15°C~+120°C - Water supply and pressurizing equipments, Fire hydrant, Boiler water supply equipments

- Industrial circulating pump, Cooling water pump, Manufacture process equipments, High-pressure cleaning equipments

- Beverage manufacturing equipments, RIO filters, Sprinklers

특징

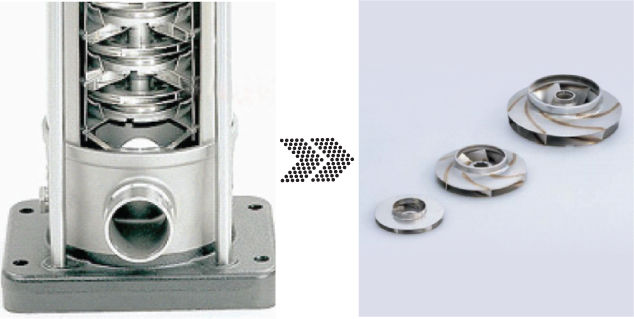

- Self priming vertical multi-stage centrifugal pump

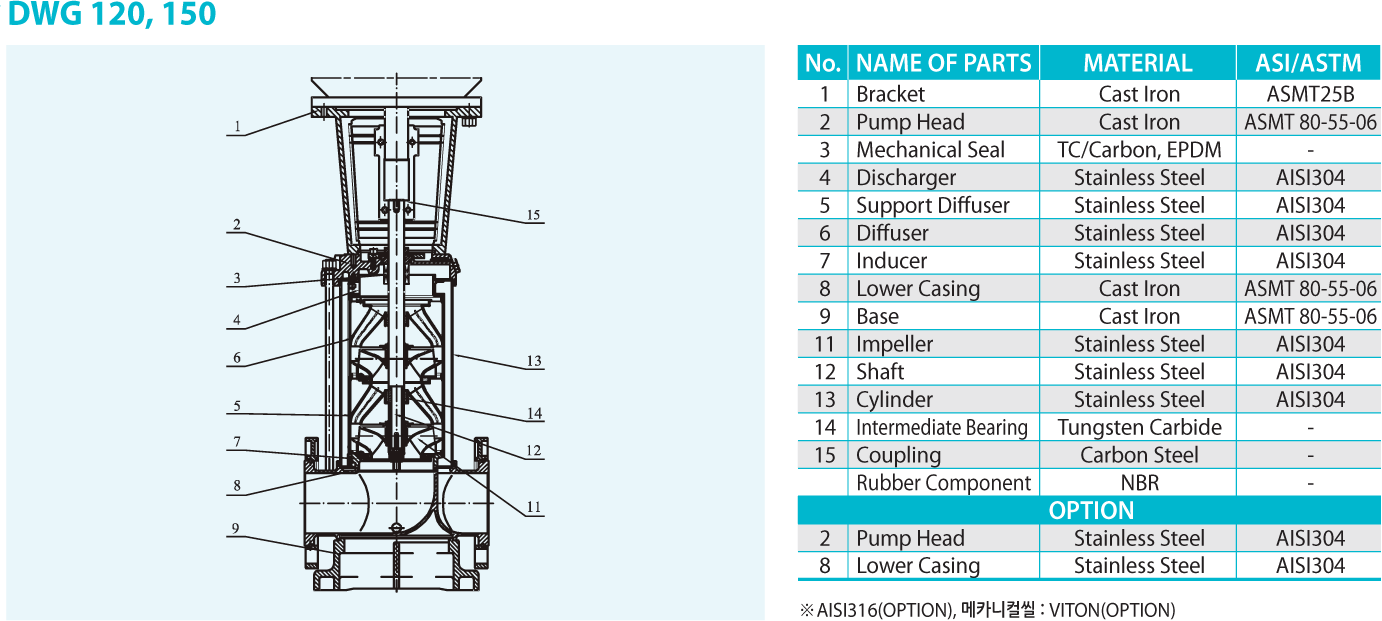

- All components that contact fluid are made of stainless steel

- Inlet and outlet have the same diameter and in-line type structure.

- Pump and motor are connected vertically, which minimizes the installation space.

- Low noise and low vibration with simple structure and accurate balance

- Excellent durability and appearance with stainless steel

- Standardized components with excellent compatibility

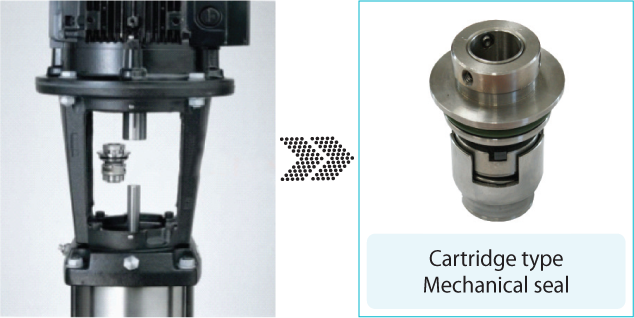

- Easy maintenance by replacing the mechanical seal,11kW pumps do not need motor separation

- Optimum pump efficiency and performance by line welding the impeller with laser Applied by model

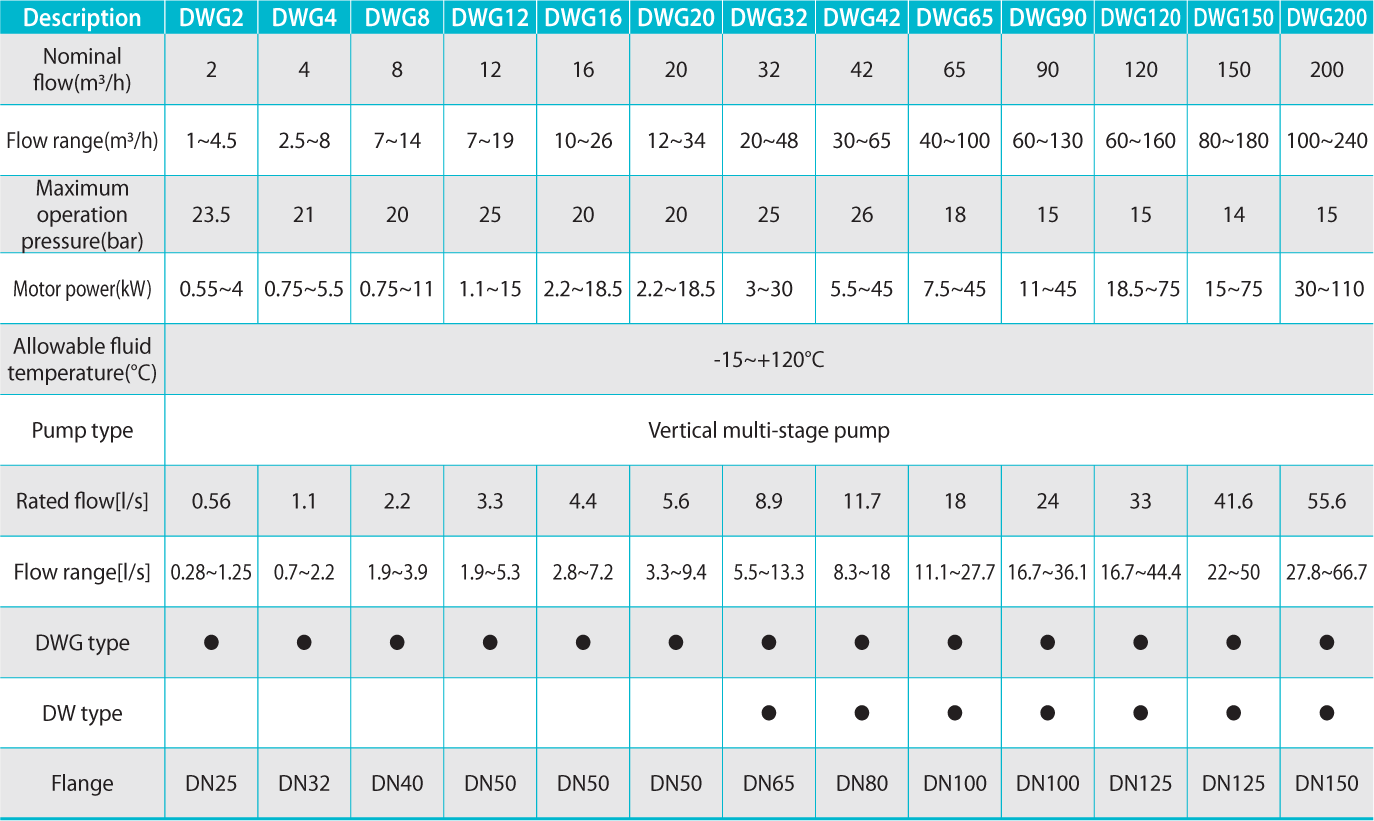

TECHNICAL DATA

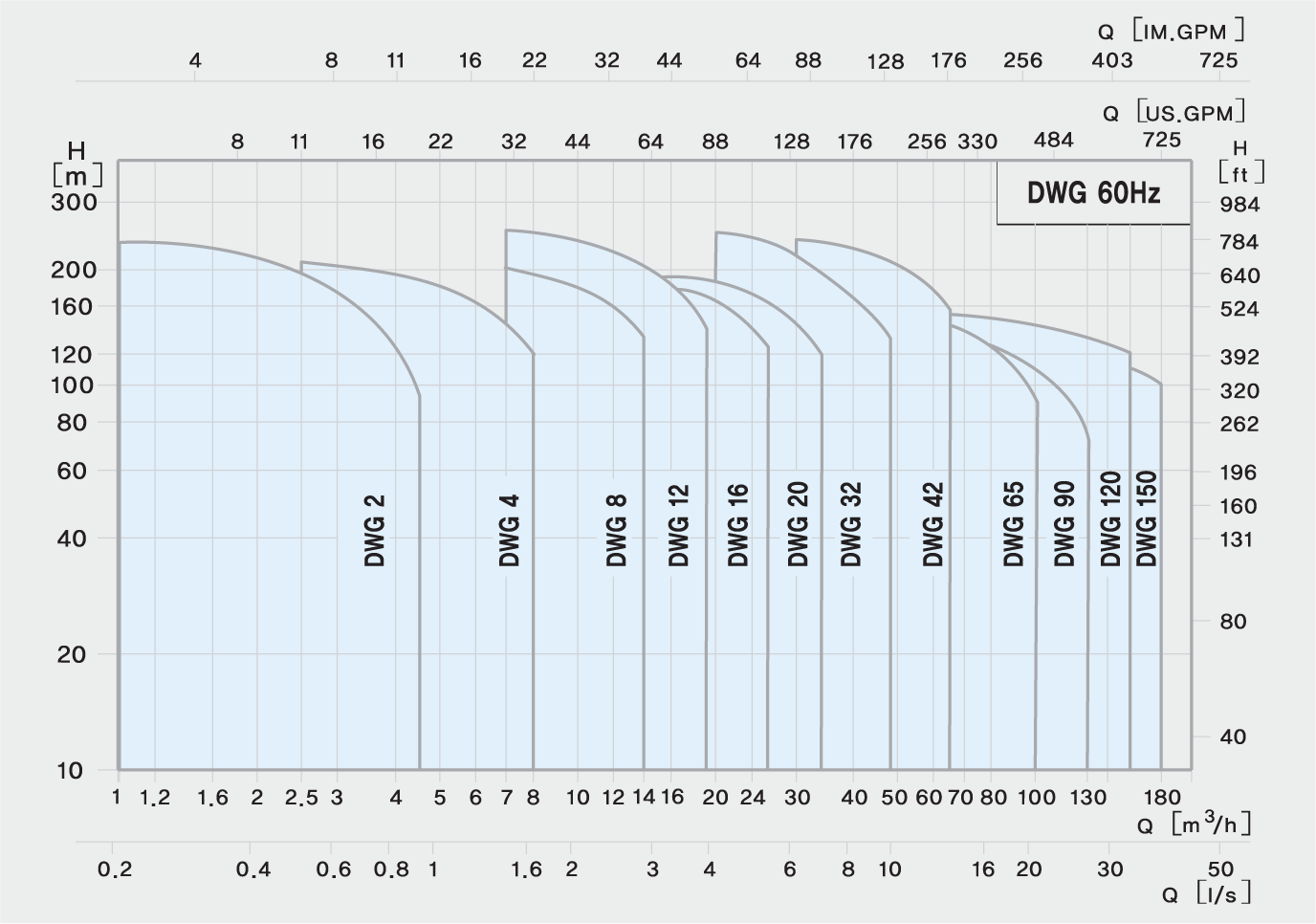

- Flow rate : Max. 180m3/h

- Lift : Max. 257m

- Temp. : -15°C~+110°C

- Maximum pressure : 25bar

- Motor power: 0.75kW~22kW(1HP~30HP)

- Control method : Pressure, Differential pressure

MAIN FUNCTIONS

- Pressure setting

- Pump speed control according to load variation

- Multi-pump interworking (max. 6 pumps)

- Anti-idling pump

- Automatic reset after error occurrence

- Motor and inverter protection

- Operating status and error display and record

- External communication (RS485, Internet control)

ADVANTAGES

- Excellent energy reduction (max. 70%)

- Optimum pump performance according to workloads

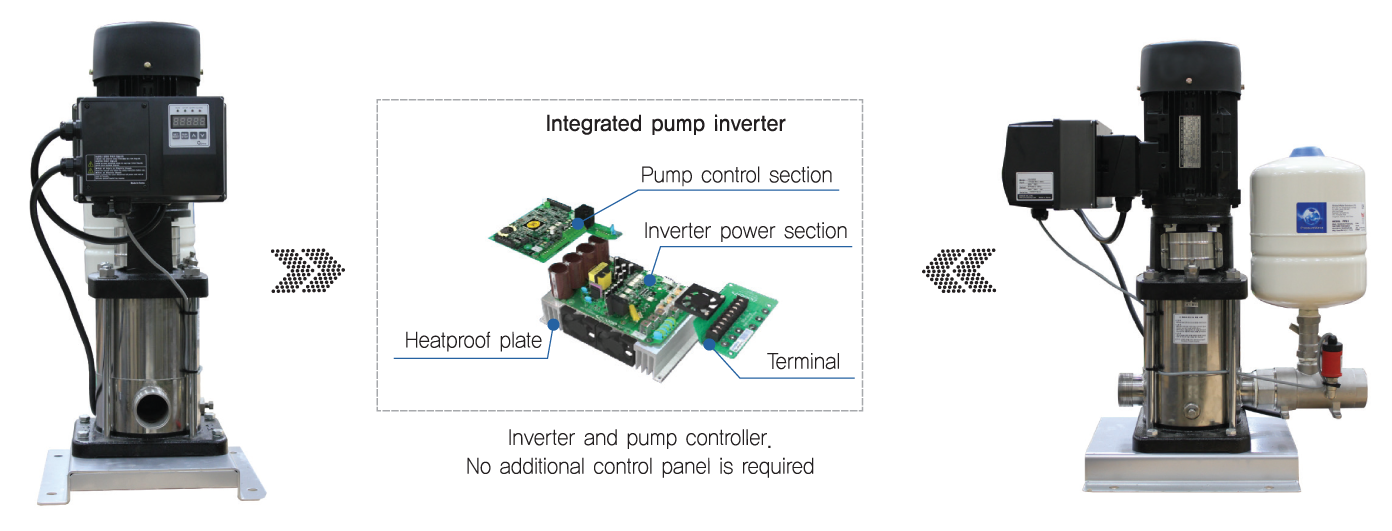

- Anti-water hammering and low noise operation Equipments used for the existing systems are not required. ex) Additional control panel, control valve

- Reduced installation spaces with compact structure

- Various applications

- Pump system life extension

- Easy installation and operation

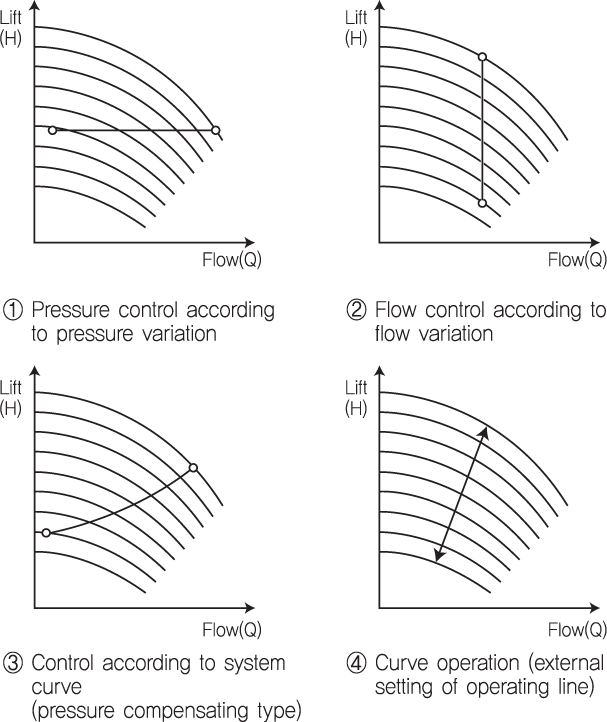

FEATURES ACCORDING TO VELOCITY VARIATION AND CONTROL METHOD

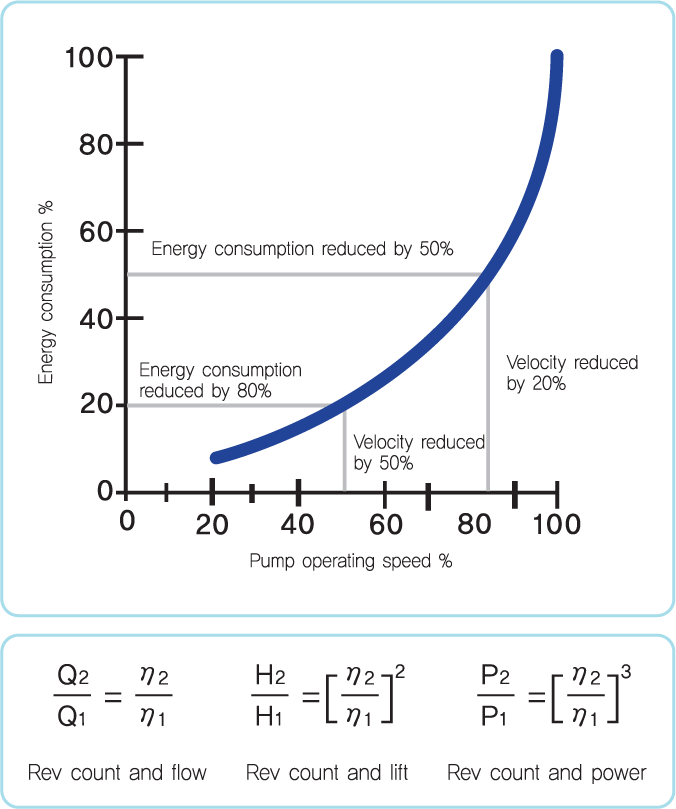

ENERGY CONSUMPTION CURVE ACCORDING TO PUMP VELOCITY VARIATION

- If rotative velocity decreases by 20% according to flow or lift variation, energy consumption decreases by 50%.

PERFORMANCE CURVE

STANDARD SPEC

플랜트산업펌프

DVMP Series

Booster Pump System Control Methods

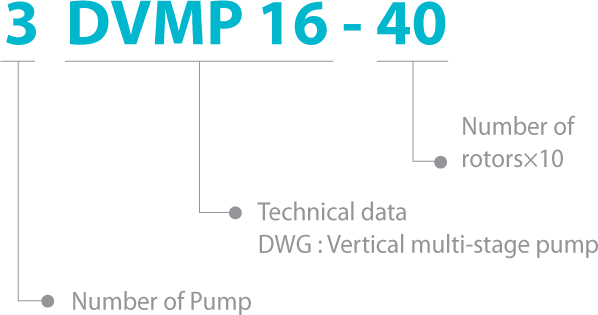

표준형식

PRESSURE TANK

특징

- Latest pump inverter model built-in

- All pumps control the rev count

- Maximum number of pumps (max. 6EA)

- Signiᴀcantly reduced operation costs(Energy Saving)

- Normal operation in emergency situations

- Small panel/tank size

- Improved system durability

- Reduced installation spaces with compact structure

MAIN CONTROL FUNCTIONS

- Constant static pressure control

- Alternating operation of main pump

- Split operation of pumps(ALL-PID)

- Skip of malfunctioning pumps

- Automatic reset after blackout

- Anti-idling of pumps(with water shortage sensor)

- Anti-sticking of pumps

- Anti-freezing of pumps

- Alarm for malfunctioning pumps

- Operation data saving

- External communication(Internet, RS485)

표준사양

| Installation space | Indoor |

| Surrounding temperature | +5°C~+40°C |

| Used liquid | Clean water |

| Used liquid temperature | 0°C~70°C |

| Maximum pressure (Suction head+Total pump head) |

20Kg/㎠ / 10Kg/ ㎠ |

| Maximum suction pressure | 0.2Kg/㎠ |

| Allowable suction pressure | Restricted according to the maximum pressure |

| Pump | Vertical/horizontal multi-stage centrifugal pump |

| Number of connected pumps | 2~6EA |

| Power | 3Ph×380V×60Hz |

| Inlet · Outlet | Stainless steel pipe |

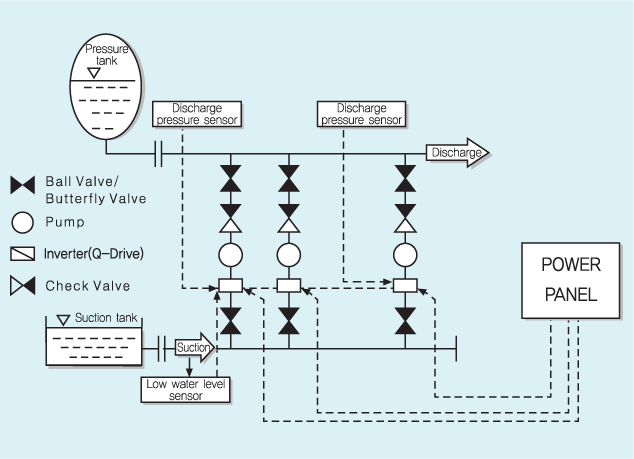

SYSTEM CONCEPT

BOOSTER PUMP CONTROL PANEL

FEATURES OF CONTROL PANEL

- Inverter(frequency converter)-controlled operation

- Connection of max. 6 pumps

- Language selection(Korean, English, Chinese)

- Fault display on LCD screen

- PC communication function(local) : OPTION

- External communication function(remote) OPTION

DETAILED SPEC

| Input Voltage | AC200V 3PH, AC380V 3PH, AC440V 3PH(50Hz, 60Hz) |

| Output Power | 1~20HP, 25~75HP(Y-△) 100HP~(SOFT STARTER) |

| Pressure Transmitter | 2선, 4-20mA, 0-50BAR |

| Remote Control | RS232c/RS485, MODEM(Option) |

MAIN CONTROL FUNCTIONS